Preparation and Characterisation of Graphene films and tapes

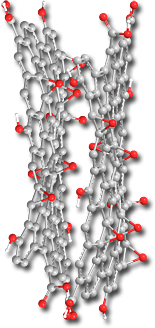

Free-standing paper-like or foil-like materials based on modifications of elemental carbon draw a great attention over the last years. Their proposed or already implemented uses include protective layers, chemical filters, components of electrical batteries or supercapacitors, adhesive layers, electronic or optoelectronic components, and molecular storage. Similarly to buckypapers prepared from carbon nanotubes by vacuum filtration, a free-standing membrane can be made by a flow-directed assembly of individual graphene or graphene oxide sheets.This new material outperforms many other paper-like materials in stiffness and strength. Its combination of macroscopic flexibility and stiffness is a result of a unique interlocking-tile arrangement of the nanoscale sheets.

Free-standing paper-like or foil-like materials based on modifications of elemental carbon draw a great attention over the last years. Their proposed or already implemented uses include protective layers, chemical filters, components of electrical batteries or supercapacitors, adhesive layers, electronic or optoelectronic components, and molecular storage. Similarly to buckypapers prepared from carbon nanotubes by vacuum filtration, a free-standing membrane can be made by a flow-directed assembly of individual graphene or graphene oxide sheets.This new material outperforms many other paper-like materials in stiffness and strength. Its combination of macroscopic flexibility and stiffness is a result of a unique interlocking-tile arrangement of the nanoscale sheets.

Incorporation of graphene particles in a semi solid thermosetting polymeric matrix will allow the manufacture of thin films combining high in-plane electrical and thermal conductivity with formability over highly and doubly curved surfaces. Thermosetting matrices offer the possibility of tuning and controlling the rheological behaviour to achieve optimal film properties with regards to manufacturability, whilst shaped films can be cured to attain the necessary rigidity. The interaction of graphene with epoxy matrices becomes of particular interest given the existence of epoxide groups in graphite oxide used as a precursor for graphene production. Direct participation of exfoliated oxide in the curing reaction offers unique opportunities for tailoring the interface between the polymeric matrix and graphene. In this regard, the influence of the existence of functional groups on the electronic properties becomes a central issue.

Two routes for the production of stable graphene suspensions, which are a prerequisite for the both aforementioned film types, are explored in CNM. Sequential chemical oxidation of common graphite to graphite oxide followed by ultrasonic exfoliation and reduction (thermal/chemical) to graphene is a more promising one. A direct ultrasound exfoliation of graphite to graphene with the aid of surfactants produces is more difficult to control, though it provides nanoscaled graphite sheets easily. A precise tunning of size of individual sheets and an exact control of their both in-plane and out-of-plane functionalization in essential for a successful fabrication of graphene-based films with desired properties.

Researchers involved:

• Otakar Frank

• Sarah Zehar