Modification of CNTs

Carbon nanotubes (CNTs) have attracted great interest because of their unique mechanical and electronic properties. They show a very high aspect ratio (length-to-diameter) and they have been shown to participate in applications such as in sensing, nanoelectronics and mechanical reinforcement of various matrices. However, manipulation and processing of CNTs has been limited by their insolubility in most common solvents, although some dissolution has recently been obtained.

Carbon nanotubes (CNTs) have attracted great interest because of their unique mechanical and electronic properties. They show a very high aspect ratio (length-to-diameter) and they have been shown to participate in applications such as in sensing, nanoelectronics and mechanical reinforcement of various matrices. However, manipulation and processing of CNTs has been limited by their insolubility in most common solvents, although some dissolution has recently been obtained.

For the production of CNT/polymer composites, highly purified material is necessary, whereas the chemical inertness of the graphitic network presents a major challenge when it comes to composite material fabrication. The oxidation of CNTs either by various oxidative methods has gained a lot of attention in an attempt to purify and also enhance the chemical reactivity of the graphitic network with the surrounding polymeric matrix. The presence of oxygen-containing groups facilitates the exfoliation of CNT bundles in solution and affects the manipulation of CNT material by enhancing the interfacial adhesion between the filler and the matrix.

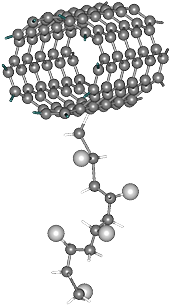

“Grafting from” approach: We have successfully applied the ceric ion-induced redox radical polymerization approach for the efficient grafting of polymer chains onto CNT sidewalls, which has led to derivatives with very high solubility in organic solvents and also in water. Besides being very powerful, this approach proved consistent for all types of CNTs tested, including single-wall (SWCNTs) and multiwall (MWCNTs) carbon nanotubes.

Oxidation of CNTs: Our group has performed a systematic study of the wet chemical oxidation of MWCNTs treated by various reagents that possess different degrees of oxidation power. Regulation of the amount of oxygen onto the CNT sidewalls is a prerequisite for building certain functional nanoscale structures and devices under special conditions. To modify the CNT surface, we treated the pristine material with several oxidative agents and studied the structural integrity of the modified tubes. Characterization of the adducts showed that it is possible to actually tune the oxygen-containing functionalities to the CNT sidewalls and tips.

Plasma treatment: In contrast with chemical and electrochemical oxidation processes that require several hours of exposure to wet conditions to reach maximum level of treatment, plasma treatment is a non-wet process that requires only some seconds of exposure to achieve the same results.